Description

100kg/cm High Torque Servo Kit Steel Gear DC12V-24V with Potentiometer For Mechanical Arm Robot

Attention: Default Setting: PWM input signal with pulse width 1-2ms.

Description:

High torque steering servo can be applied to mechanical arms, PTZ, UAV, unmanned vehicles, remote control cars, AI devices and the like.

It is designed with steel metal gears. With metal shell, brush motor prolongs its life span. With digital circuit, its driver stands out in response and long travel, and is compatible with remote control systems on the market.

Unique power stabilization technology ensures that the servo works normally after being over-loaded. Once you remove the over-loaded part, it reworks automatically. Thanks to its premium quality, gears are not likely to be damaged after being over-loaded.

It supports PWM 1-2MS pulse signal control (standard servo control signal) and analog voltage signal control 0-5V. With BEC 5V output, it can power your receiver.

Main Parameters:

Power Supply Input: 12V-24V DC (V- connects to negative electrode. V+ connects to positive electrode)

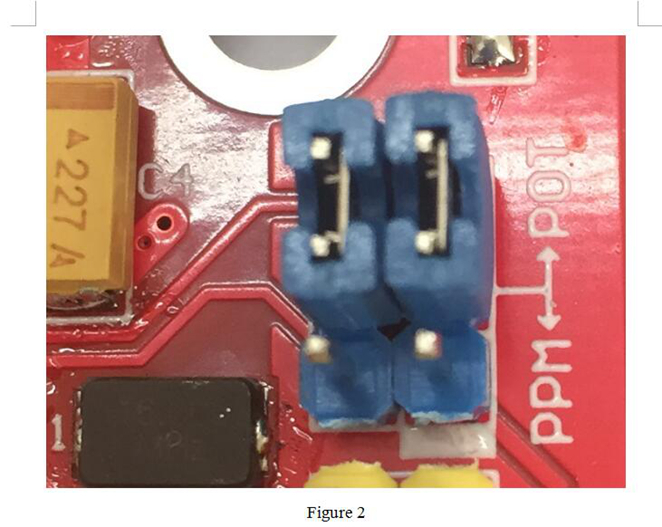

Figure 2: Mode Selection.

PPM is for pwm pulse signal input. POT is for analog voltage signal input. It is in analog voltage signal input (potentiometer) mode when you move blue jumper cap to POT. It is in pwm signal input mode, when these two jumper caps are moved to PPM.

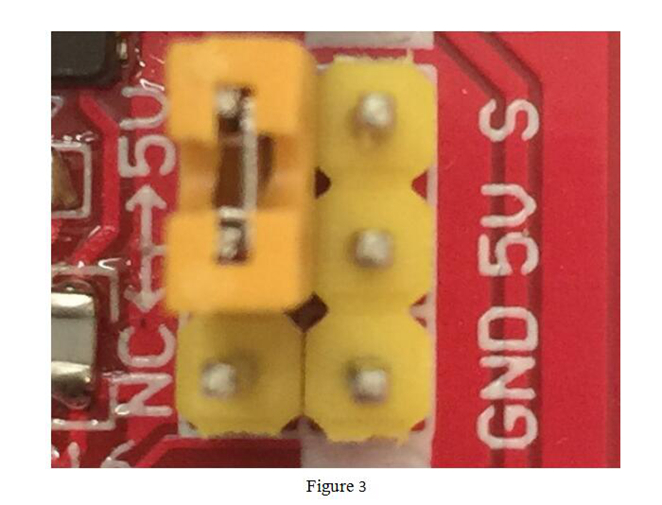

Figure 3: 5V Mode Selection.

It can be set to output with 5V or without 5V. When yellow jumper cap moves to 5V, it outputs 5V on the right side. When the jumper cap is moved to NC, there is no 5V output on the right side.

Attention: When the potentiometer is used, please switch to 5V output mode.

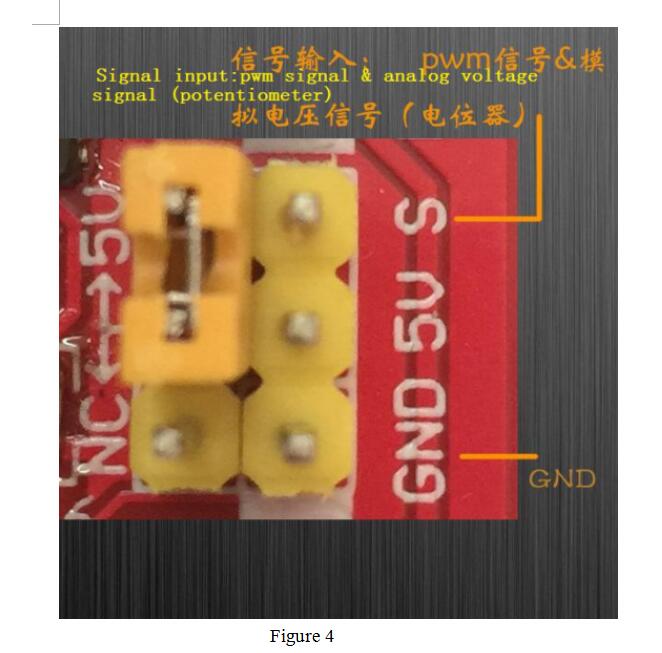

Figure 4: Signal Input Pins.

- S Signal Input: Refer to Figure 2 if you want to input pwm or potentiometer signal.

- 5V: Output 5V. Refer to Figure 3 if you want to output with 5V or without 5V.

- GND: Ground, negative electrode.

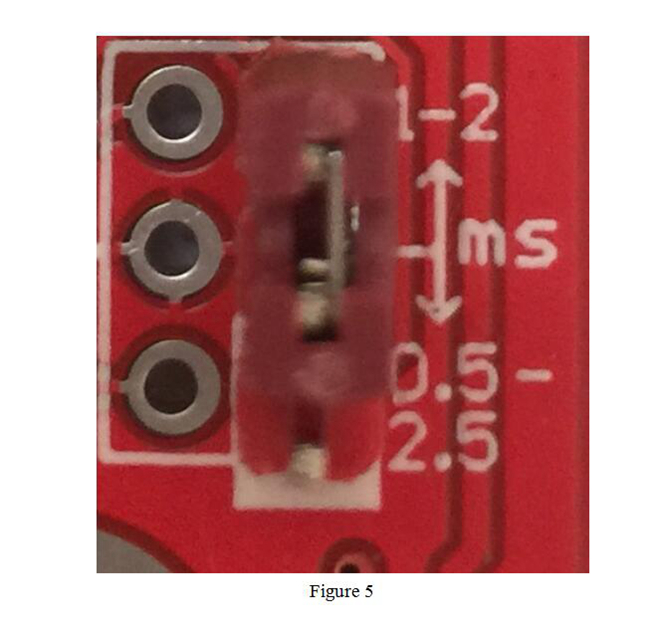

Figure 5: Pulse Width Mode Selection.

ms:used to switch the pulse size of PWM signal input port. It can switch between 1-2ms and 0.5-2.5ms. You can select pulse width modes to meet your needs. When your RC receiver outputs 1-2ms PWM, it cannot reach 270° in 0.5-2.5ms mode. So it can switch to 1-2ms mode and the maximum angle of the servo is 270°. It is recommended to switch to 0.5-2.5ms mode to match servo controllers with 0.5-2.5ms or 0.5-2.1ms output. 0.5ms-2.5ms mode is perfect for multi-way servo controllers, some RC

remote controllers, MCU programming and for Arduino.

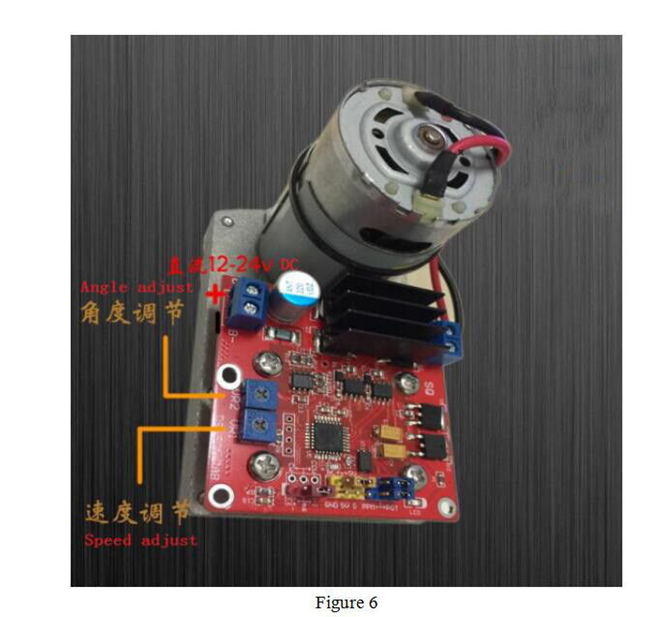

- Angle Adjustment: Turn it clockwise and angle increases. Turn it counterclockwise and angle decreases. Please control both sides at the same time to decrease and increase.

- Speed Adjustment: Turn it clockwise and speed increases. Turn it counterclockwise and speed decreases.

- Power Supply Port: Connects to 12V-24V DC power supply. The current of your power supply should be ≥ 5A. 5A is permitted for no-load. For on-load, please use power supply ≥10A. Reverse connection is forbidden.

Note: Servos have passed strict tests before hitting the market. Please not disassemble or modify the servos. Thank you!

Parameters:

- Angle: 270°

- No-Load Current: <500mA

- Max. Torque:

110kg/cm (24V) Actual Measurement;

1078N/cm;

55kg/cm (12V) Actual Measurement;

539N/cm.

- Angular Speed: 0.12s/60° @24V; 0.24s/60° @12V

- Gear Material: Steel

Features:

- Power Supply: DC12-24V

- Rotation Speed: 40-80rpm

- Diameter of Output Shaft: 8mm

- Gear motor with all metal gears

- Simple motor's structure for long service life and easy maintenance

- Universal gear box's structure for easy installation

- High speed and high torque but with low power consumption

- Low-noise operation

- Only weighs 530g

Package Included:

- 1 x Servo

- 1 x 20cm Signal Cable

- 1 x Potentiometer

- 1 x Bracket

- 1 x Servo Horn

- 1 x Servo Extension Cable

380kg.cm High Torque Servo Steel Gear DC 12V-24V with Potentiometer For Robot Mechanical Arm

Functions:

- Comes with a potentiometer

- Supports potentiometer & remote control

- Adjustable current and angle

- CW and CCW switching, AD & PWM switching, pulse width 1-2ms & 0.5-2.5ms

- Stable performance and smooth operation with powerful anti-interference ability

- Perfect for Futaba, JR, SANWA, Hitec and other remote control systems

Parameters:

- Working Voltage: DC12-24V

- No-Load Current: <500mA

- Maximum Torque(Actual Measurement): 380kg.cm(24V) ;1764N.cm(24V); 90kg.cm(12V); 882N.cm(12V)

- Angular Speed: 0.6S/60° @24V; 0.6S/60° @12V

- Rotation Angle: 300° MAX. (Adjustable)

- Input Modes:

PWMIN is PWM pulse signal (For remote controllers, multi-way servo controllers & MCU);

ADIN is analog voltage signal(potentiometer).

-Pulse Signal Input Range: 0.5ms-2.5ms for multi-channel controller, for 1ms-2ms RC controller, MCU programming, Arduino and the like

- Voltage Signal Input Range: 0 to +5V

- Control Accuracy: 0.5°

- Weight: 530g

- Gear Material: Steel

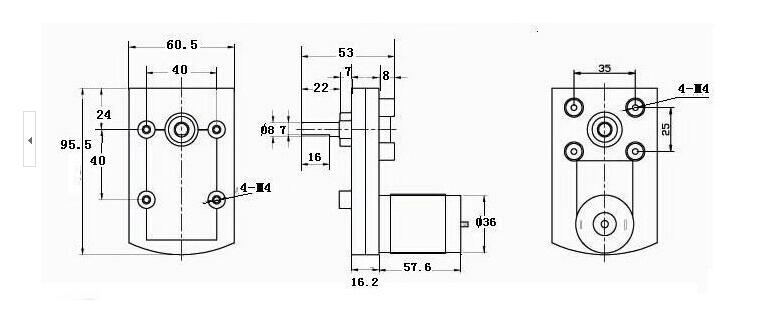

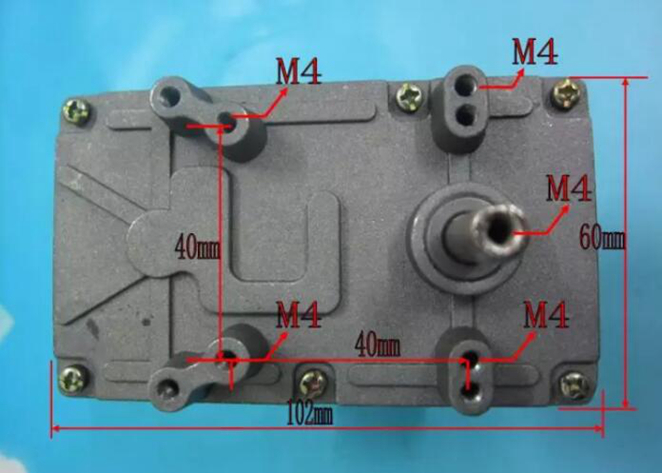

- Size: 95.5 x 60.5 x 102.6mm

Application:

- For medium to large robots, mechanical arms and other fields requiring high power and high torque control.

- Power Supply Input: DC12-24V.

- Motor Output: OUT1 to motor -; OUT2 to motor +.

-Mode Selection: Select pulse signal input or analog voltage signal input by jumper cap. PWMIN is for pulse signal input. ADIN is for analog voltage signal input.

- Analog Control Mode: Angle input signal is analog. A potentiometer is used to control the angular position of motor's axle.

- Digital Control Mode: Angle input signal is digital square wave signal with pulse width 0.5ms-2.5ms or 1ms-2ms.

Package Included:

- 1 x Servo

- 1 x Signal Cable

- 1 x Potentiometer

- 1 x Bracket

- 1 x Servo Horn

- 1 x Servo Extension Cable