Description

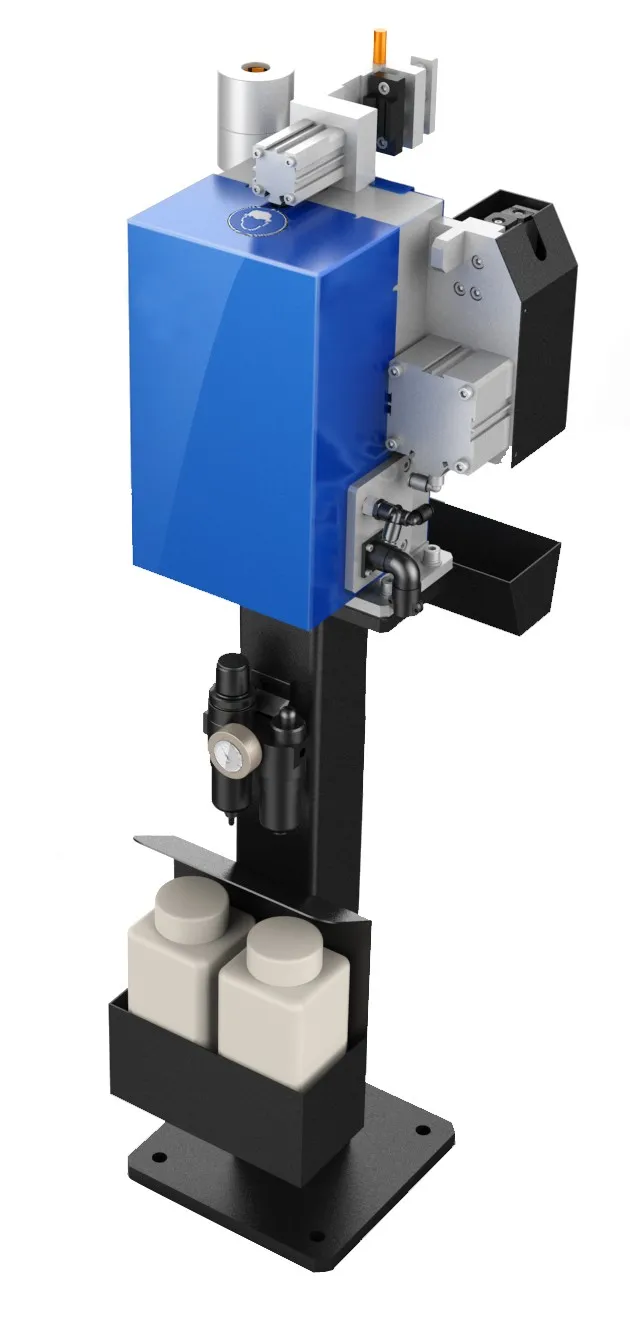

Robot welding Torch cleaning station TCS - PPplug-in and Play.The machine equipment

video:https://www.youtube.com/watch?v=bOp4ZLu0e_s

product presentation:

1 Identification

The torch cleaning station TSC-PP is used in industry and in the trade for automatic cleaning of the gas

nozzle interior of MIG/MAG welding torches. The TSC-PP serves as a preventive measure to extend the

service lives of the torches and the maintenance intervals. The TSC-PP consists of:

• the cleaning unit

• the injection unit VI

• the wire cutter DAV

The TCS-PP "Plug and play" Torch Cleaning Station offers the complete solution for reliable automatic servicing of the torch neck. Combined in a single station, the 3 point clamping system guarantees optimally timed processes and an increase in available floor space. A number of other features such as a mounting stand and drip pan reduce installation costs

function:

1. Torch Cleaning Station

1 :Precise and effective cleaning for almost all robot welding torches.

2:Precise and effective cleaning for almost all robot welding torches.

3 :Proven and trusted cutter principle, suitable even for heavy spatter adhesion.

4 :3-point clamping of the gas nozzle fixes the torch in place during the cleaning process.

2. Spraying unit "TMS-VI"

1: Direct, economical spraying of all anti-spatter fluid reduces welding spatter adhesion and extends the service intervals

2: Clean environment thanks to encapsulated spraying nozzle and collecting pan for dirty residual oil.

3: Simple disposal of residual oil and replenishment of the anti-spatter agent by simply exchanging the bottles.

3. Wire Cutting fixture "WCS"

1:The combined clamping and shearing action guarantees precise cutting quality and ensures optimum arcstart properties as well as exact TCP measurement.

2 :Long service life thanks to a sturdy design.