Description

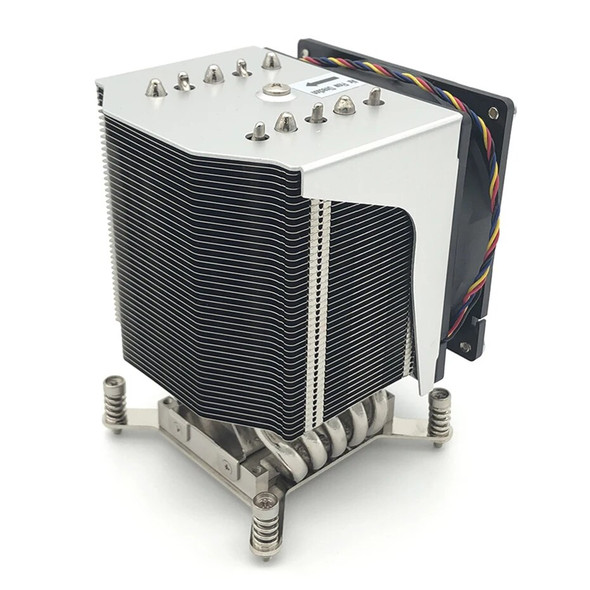

COOLSERVER R17 R18 2U Server CPU COOLER 3 Heatpipes 130w Desktop Case silent fan For LGA2011 Workstation Computer Radiator

Product model: LGA2011-R17

CPU type: LGA2011 (square motherboard)

Voltage: 12V

Product size: 90mm*90mm*64mm

CPU hole spacing: 80mm*80mm

Fin thickness: 0.4mm

Fin pitch: 3.0mm

Power consumption: 110W

Number of heat pipes: 3

Material: aluminum base + aluminum fins + 3 heat pipes

Product model: LGA2011-R18

CPU type: LGA2011 (rectangular motherboard)

Voltage: 12V

Product size: 104mm*80mm*64mm

CPU hole distance: 56mm*94mm

Fin thickness: 0.4mm

Fin spacing: 2.5mm

Power consumption: 110W

Number of heat pipes: 3

Material: aluminum base + aluminum fins + 3 heat pipes

COOLSERVER 2U radiator /3 heat pipe + Reflow welding process + Nickel plating fin

3 composite heat pipes were used

Better heat conduction ability, better excellent heat conduction and heat dissipation performance

3 high efficiency heat pipes closely cover the CPU surface, greatly increasing the contact area, so that the heat is more efficient to the heat dissipation fin.

Nickel plating technology of heat pipe

The design of three composite heat pipes, through the surface treatment of nickel plating, increases the contact between magnesium light and anti-oxidation heat pipe, effectively improve heat conduction efficiency of heat pipe.

Reflow welding process is adopted

Better contact, stable thermal conductivity, high thermal conversion rate, efficient heat dissipation

The heat-conducting copper pipe and the base adopt reflow welding process, high precision and tight joint, full solder, fine workmanship, improve the heat conduction efficiency of CPU to the heat dissipation fin.

Base conducts heat quickly

Zero distance contact of the base helps the CPU generate heat the first time!Conduction around

Attach to CPU heating core, absorb and conduct every minute of heat in time

Heat sink fin electroless nickel plating treatment

1. The metal surface treated by this process is amorphous coating with excellent corrosion resistance

2. As the surface of the catalytic treatment is amorphous, that is, in the basic plane state, with self-lubrication, therefore, the friction coefficient is small, non-adhesion is good, high wear resistance

3. After electroless plating, the hardness of metal surface can be increased by more than one time

4. The combination strength of alloy layer and metal base parts increases after electroless plating. Generally, under the condition of 350-400mpa, there is no peeling, no shedding, no bubble, and the combination strength of aluminum can reach 102-241mpa.