Description

Anycubic Wash & Cure 3

Refresh Your

Post-process Experience

Extra Large | Gooseneck Lights | IPA-saving

Larger Size for Upgraded Capacity

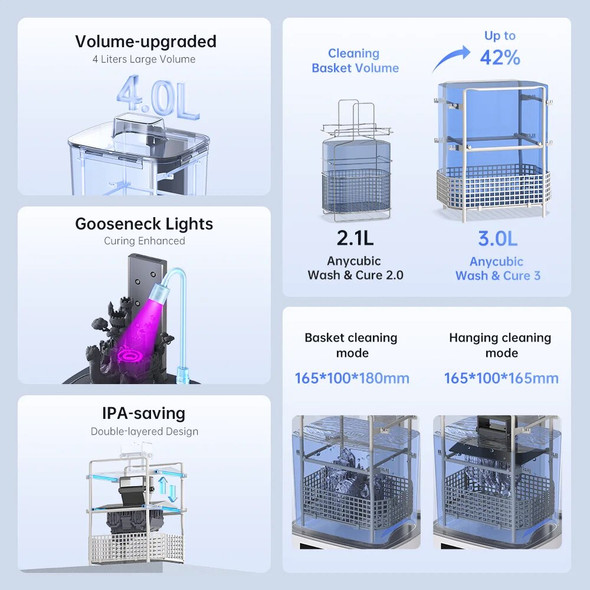

Compared to Anycubic Wash & Cure 2.0, the Anycubic Wash& Cure 3 has an impressive 100% increase in cleaning basket capacity, now at 3 liters. The total volume of the cleaning bucket has been expanded to 4 liters. This makes it perfectly tailored for LCD (light-curing) 3D printers with a size of 7.3 inches or less.

The curing size has increased by 15%, up to 160*180 millimeters, to accommodate larger and more models for single post-processing session.

Localized Strengthening, Uniform Curing

The "Innovative Flexicure Gooseneck Light Design" increases the energy value by 30,000uW/cm² within a 1-3 cm irradiation range, significantly strengthening the curing effect on subtle areas such as the top of models and the hem of garments.

*Data sourced from Anycubic Laboratory

By adopting a brand-new arrangement of light beads and lens light source, Anycubic Wash & Cure 3.0's curing uniformity has been enhanced by 20%* compared to its predecessor 2.0. This results in a more thorough and comprehensive curing of the entire model.

Dual-layer Design, IPA Saving

The double-layered PP material cleaning basket is designed to support simultaneous cleaning with the platform. It features two adjustable heights at 100mm and 165mm, providing flexibility to accommodate printing platforms ranging from 5.9 inches to 7.3 inches. This design maximizes the efficiency of IPA usage.

Cleaning basket made of PP material (rust-resistant) VS the previous generation's metal material (prone to rust)

Simple Operation, Quiet and Efficient

Cleaning and curing dual modes, easily selected with one click; Enhanced Gooseneck light curing mode can be easily toggled on and off with one click. Infinite rotary knob control, adjustable from 1 to 30 minutes at will.

Through a more sealed structural design and software optimization, the noise interference generated during cleaning and curing is reduced, creating a quieter and more comfortable working environment.

Machine Model Comparison